Accessories of Centrifugal Air Blowers

- Home

- Products

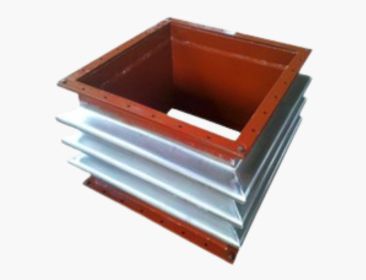

Expansion Bellow

Expansion Bellows are flexible connectors used to absorb thermal expansion, vibrations, and misalignments in ducting systems. Engineered for durability, they ensure safe and efficient operation in ventilation and exhaust setups. Ideal for industrial applications requiring flexibility and precision.

Suction Filter

Suction Filters are critical components used to remove dust, debris, and other contaminants from the air before it enters the blower or fan system. They ensure clean airflow, protect equipment, and enhance system efficiency in industrial ventilation and dust collection setups.

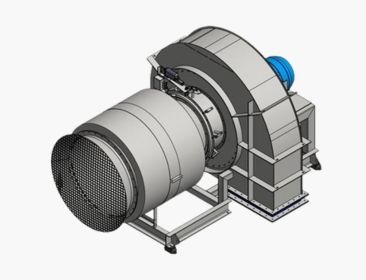

Silencer

Silencers are designed to reduce noise generated by high-velocity airflow and mechanical vibrations. Engineered with acoustic insulation and aerodynamic design, they ensure quieter operation in industrial ventilation and air-handling systems without compromising airflow efficiency.

Damper

Dampers in centrifugal blowers are used to control and regulate the volume of airflow within ducting systems. They enhance operational efficiency by allowing precise modulation of air supply and pressure. Ideal for industrial ventilation, they help maintain optimal performance and energy savings.

Vibration Isolator

Vibration isolators are used in industrial centrifugal blowers to reduce the transmission of vibrations to surrounding structures. They enhance equipment stability, extend machinery life, and ensure quieter operation by absorbing mechanical shocks and dynamic loads. Essential for maintaining performance in heavy-duty ventilation systems.

Pulley

Pulleys in industrial centrifugal blowers transmit rotational power from motors to blower shafts using belt drives. They enable speed control, reduce vibration, and ensure reliable performance in air-handling systems. Made from robust materials like cast iron or steel, these pulleys are built for high-load applications.

Coupling

Couplings are used to connect the motor and blower shafts, ensuring smooth power transmission while compensating for minor misalignments. In industrial centrifugal blowers, flexible couplings help reduce vibration, prevent wear, and enhance operational efficiency. Common types include Pin Bush, Grid, and Tyre couplings.

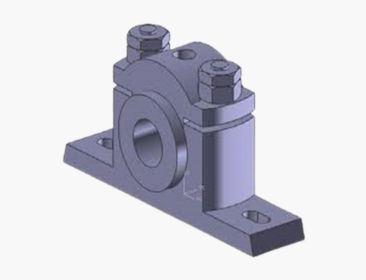

Pedestal

Pedestals in centrifugal blowers support the shaft and bearing assembly, ensuring alignment and stability during operation. They are designed to withstand high loads and vibrations, enhancing reliability and extending the life of rotating components. Typically made from cast iron or steel for robust industrial use.

Shaft Cooler

Shaft Coolers, also known as Heat Slingers, are mounted on blower shafts to dissipate heat generated during high-speed operation. By directing airflow across bearing housings, they help prevent overheating, protect lubrication integrity, and extend the life of critical components in industrial blower systems.

Operational Range

- Air Flow (Capacity) : 100 CMH to 200000 CMH

- Static Pressure Range : 10 mmWC to 1500 mmWC

- Motor : up to 150 HP

- Max RPM Range : up to 3000 RPM

- Construction Material of Casing : Mild Steel and Stainless Steel

- Construction Material of Impeller : Mild Steel and Stainless Steel